Page 87 - Hitachi IR 2025

P. 87

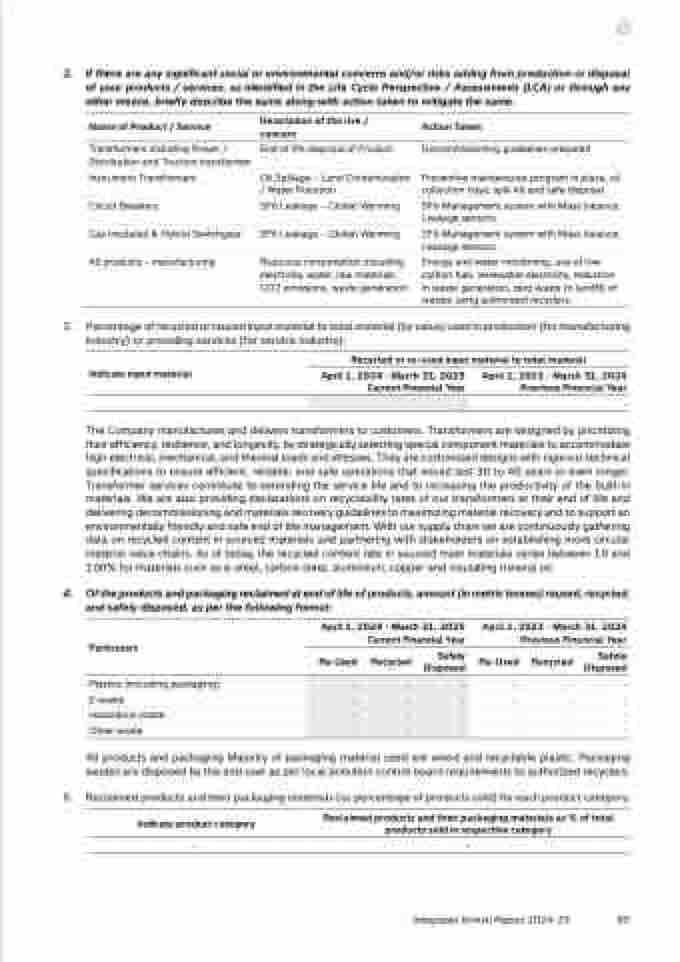

2. 3. 4. 5. If there are any significant social or environmental concerns and/or risks arising from production or disposal

of your products / services, as identified in the Life Cycle Perspective / Assessments (LCA) or through any

other means, briefly describe the same along-with action taken to mitigate the same.

Name of Product / Service Description of the risk /

concern

Action Taken

Transformers including Power /

Distribution and Traction transformer

End of life disposal of Product Decommissioning guidelines prepared

Instrument Transformers Oil Spillage – Land Contamination

/ Water Pollution

Preventive maintenance program in place, oil

collection trays, spill kit and safe disposal

Circuit Breakers SF6 Leakage – Global Warming SF6 Management system with Mass balance.

Leakage sensors.

Gas Insulated & Hybrid Switchgear SF6 Leakage – Global Warming SF6 Management system with Mass balance.

Leakage sensors.

All products - manufacturing Resource consumption including

electricity, water, raw materials,

CO2 emissions, waste generation

Energy and water monitoring, use of low

carbon fuel, renewable electricity, reduction

in waste generation, zero waste to landfill of

wastes using authorized recyclers.

Percentage of recycled or reused input material to total material (by value) used in production (for manufacturing

industry) or providing services (for service industry).

Recycled or re-used input material to total material

Indicate input material

April 1, 2024

-

March 31, 2025

Current Financial Year

April 1, 2023

-

March 31, 2024

Previous Financial Year

- -

The Company manufactures and delivers transformers to customers. Transformers are designed by prioritizing

their efficiency, resilience, and longevity, by strategically selecting special component materials to accommodate

high electrical, mechanical, and thermal loads and stresses. They are customized designs with rigorous technical

specifications to ensure efficient, reliable, and safe operations that would last 30 to 40 years or even longer.

Transformer services contribute to extending the service life and to increasing the productivity of the built-in

materials. We are also providing declarations on recyclability rates of our transformers at their end of life and

delivering decommissioning and materials recovery guidelines to maximizing material recovery and to support an

environmentally friendly and safe end of life management. With our supply chain we are continuously gathering

data on recycled content in sourced materials and partnering with stakeholders on establishing more circular

material value chains. As of today, the recycled content rate in sourced main materials varies between 10 and

100% for materials such as e-steel, carbon steel, aluminium, copper and insulating mineral oil.

Of the products and packaging reclaimed at end of life of products, amount (in metric tonnes) reused, recycled,

and safely disposed, as per the following format:

April 1, 2024

-

March 31, 2025

Current Financial Year

Particulars

April 1, 2023

-

March 31, 2024

Previous Financial Year

Re-Used Recycled Safely

Disposed Re-Used Recycled Safely

Disposed

Plastics (including packaging)- - - - - -

E-waste- - - - - -

Hazardous waste- - - - - -

Other waste- - - - - -

All products and packaging Majority of packaging material used are wood and recyclable plastic. Packaging

wastes are disposed by the end user as per local pollution control board requirements to authorized recyclers.

Reclaimed products and their packaging materials (as percentage of products sold) for each product category.

Indicate product category Reclaimed products and their packaging materials as % of total

products sold in respective category

- -

Integrated Annual Report 2024-25

85