Page 104 - Hitachi IR 2025

P. 104

BUSINESS RESPONSIBILITY & SUSTAINABILITY REPORT

8. 9. Does the entity have any project related to reducing Green House Gas emission? If Yes, then provide details.

The main sources of the Company’s direct (Scope 1) Greenhouse Gas (GHG) emissions are the fuels used

in our operations, such as natural gas usage and SF6 losses during production processes and gas handling

on site. Indirect (Scope 2) GHG emissions from purchased electricity. The Company recognizes the need to

limit global warming to no more than 1.5°C above pre-industrial levels, in order to avoid the worst affects

of climate change. As such, our ambition is to become carbon neutral in our own operations by 2030 and

achieve Net Zero across the entire value chain by 2050. To achieve this, we have implemented several projects

and initiatives which include: Solar roof top installations at Maneja where 932 kW and Doddaballapur where

600 kW were commissioned. Mysore facility has Power Purchase Agreements which caters to nearly 90%

of its electricity requirement. The remaining carbon from grid electricity is offset by purchasing International

Renewable Energy Certificates (IREC). Going forward the Company will focus on more direct, and potentially

value adding methods such as green tariffs, Power Purchase Agreements (PPAs) and own generation to meet

its renewable electricity targets.

At project site, solar roof top installations are used to power offices at Adani HVDC project and 6 GPQS sites

totaling 47.7 kW capacity. 6 sets solar based mobile charging facility with 3 lights and 2 USB installed in rest

sheds and worker colony and 7 CNG vehicles are used at HVDC site.

Energy conservation activities include replacing conventional lamps with LED, installation of solar lights,

electrical retrofits such as replacement of old drives and compressors with energy efficient equipment; process

improvements such as optimizing operations of HVAC and AHUs and thermal insulation of hotlines to prevent

heat loss. At Maneja, energy monitoring systems were installed to monitor energy consumption patterns and

take appropriate actions. 7 nos. of HT/LT substations and 53 Energy meter are connected to the monitoring

system. At Halo and Maneja, LPG was replaced by low carbon PNG while Mysore uses biofuel such as paddy

husk and waste dust from own operations to fuel its boilers. Replacing old R22 based HVAC systems to high

COP R410A at Maneja has also resulted in reduction in carbon emissions.

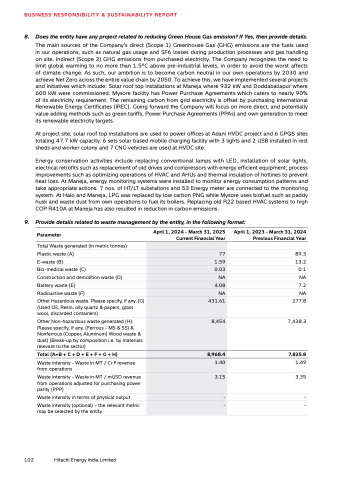

Provide details related to waste management by the entity, in the following format:

Parameter April 1, 2024

-

March 31, 2025

Current Financial Year

April 1, 2023

-

March 31, 2024

Previous Financial Year

Plastic waste (A) 77 89.3

E-waste (B) 1.59 13.2

Bio-medical waste (C) 0.03 0.1

Total Waste generated (in metric tonnes)

431.61 277.8

Construction and demolition waste (D) NA NA

Battery waste (E) 4.08 7.2

Radioactive waste (F) NA NA

Other Hazardous waste. Please specify, if any. (G)

(Used Oil, Resin, oily quartz & papers, glass

wool, discarded containers)

Other Non-hazardous waste generated (H).

Please specify, if any. (Ferrous - MS & SS) &

Nonferrous (Copper, Aluminum) Wood waste &

dust) (Break-up by composition i.e. by materials

relevant to the sector)

8,454 7,438.3

Total (A+B + C + D + E + F + G + H) 8,968.4 7,825.8

Waste intensity - Waste in MT / Cr ` revenue

from operations

1.40 1.49

Waste intensity - Waste in MT / mUSD revenue

from operations adjusted for purchasing power

parity (PPP)

3.15 3.35

Waste intensity in terms of physical output - -

Waste intensity (optional) – the relevant metric

may be selected by the entity

- -

102 Hitachi Energy India Limited